In 1980, an unusually heavy snowfall severely damaged the old wooden barn on our place. We propped the roof up and used the barn for another 10 years or so before taking it down and building a replacement.

In 1980, an unusually heavy snowfall severely damaged the old wooden barn on our place. We propped the roof up and used the barn for another 10 years or so before taking it down and building a replacement.

Most of the Douglas fir wood was damaged, but we saved the rest and have used it for various projects, plus have given a lot of it away.

Most of the Douglas fir wood was damaged, but we saved the rest and have used it for various projects, plus have given a lot of it away.

We wanted a small table with a shelf to fit between our two recliners: something more interesting than the usual fare. I decided to create a table that appeared to be rustic old. The old fir barn wood fit the bill! I chose pieces that still had some red tone from the hundred-year-old paint job.

I won’t include measurements here because you can make your table any size you want, just by following these steps.

After cutting and sanding all the pieces for the project, I glued the three top pieces together (center plus two sides). I clamped them flat and glued with wood glue.

For the end pieces, I cut a 3/8 inch slot on each end of the table and on each end piece, then splined the top and ends with (3/4 inch blade-kerf width) wood splines and glued. Once dry, I tapered the sides from center to end.

I scorched the exposed edges to continue with the vintage look. Metal pieces clamped in place prevented me from scorching the top or bottom.

I assembled the apron next, then inserted the pre-cut corner blocks. These were cut out for the leg tenons.

The table saw blade is set at 45° so that all the cuts on the legs are 45°. Meanwhile with a tapering jig against the fence, the tapering jig is set so that the leg will taper 1/4″ in its entire length as it is being cut. I screwed in tying blocks and taped them to the leg top surface to keep the leg from sliding as it was being cut. I used a homemade pushing stick to keep my hand away from the blade.

I taped the leg parts together as a test for fit, and once okay, glued and clamped.

I cut out the leg tenons using multiple passes on a table saw and then cleaned them up using a chisel. It was a tricky business with the old, brittle wood.

I assembled the top to the apron, using tape for correct placement, then screwed the apron to the table top through the pre-drilled holes in the blocks.

I inserted each leg tenon into the blocks and screwed through the pre-drilled hole in the middle.

I custom-made metal tabs that would hold the shelf using some metal scrap I had around.

The tabs were installed at the height of the bottom of the shelf.

I applied a clear lacquer finish to prevent any modern stains. I like that all the flaws are historic.

Thanks for stopping by! Be sure to check out our suspension bridge book. Here is the link:

Building a Small Cable Suspension Bridge with the Cable Locking System

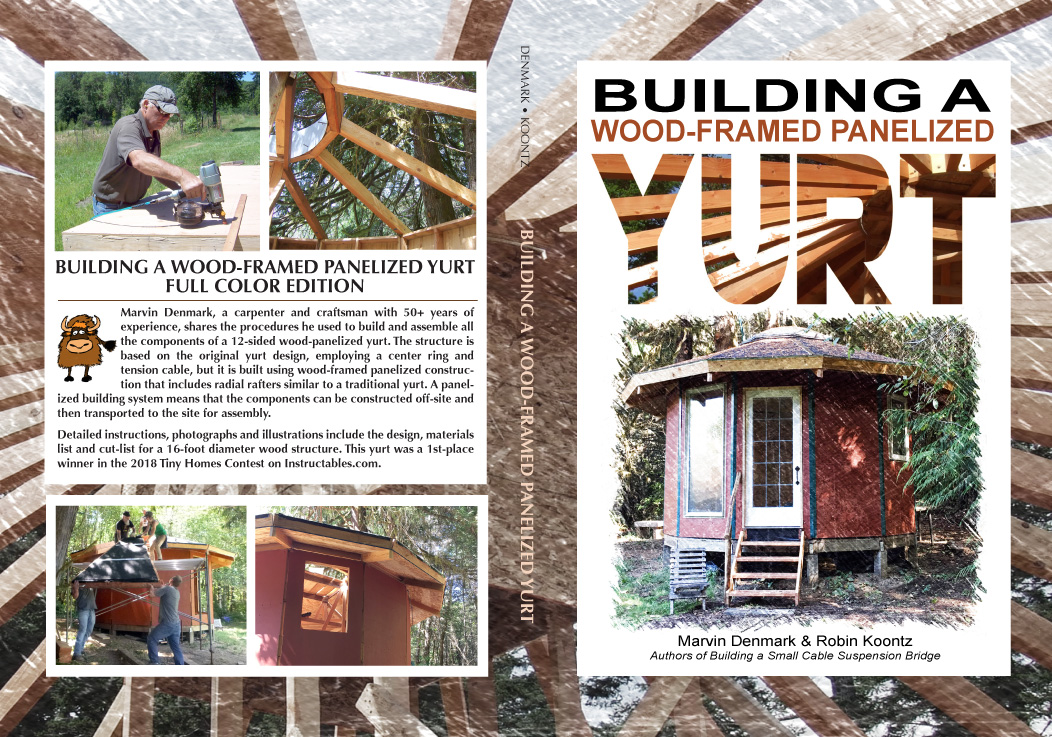

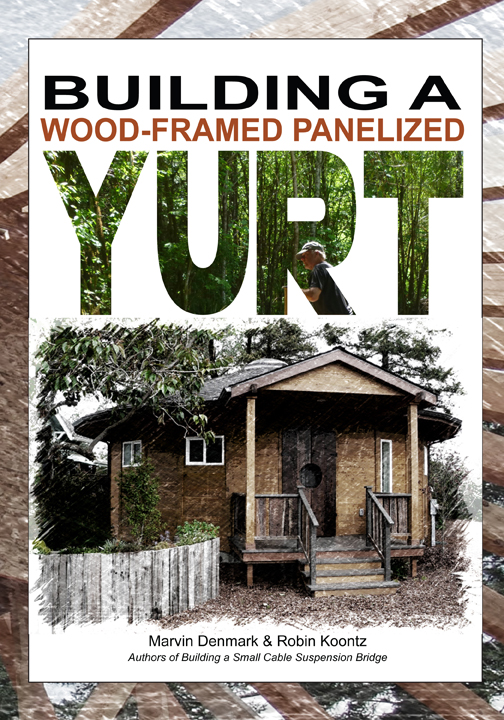

Stay tuned for the publication of our new book, Building a Wood-Framed Panelized Yurt. You can see how the yurt is progressing via Facebook’s Yurt Yaks.

Images, diagrams, and text copyright 2013-2018 by Marvin Denmark and Robin Koontz unless otherwise noted. Please do not copy and post my content anywhere without permission. Thank you.

In 1980, an unusually heavy snowfall severely damaged the old wooden barn on our place. We propped the roof up and used the barn for another 10 years or so before taking it down and building a replacement.

In 1980, an unusually heavy snowfall severely damaged the old wooden barn on our place. We propped the roof up and used the barn for another 10 years or so before taking it down and building a replacement. Most of the Douglas fir wood was damaged, but we saved the rest and have used it for various projects, plus have given a lot of it away.

Most of the Douglas fir wood was damaged, but we saved the rest and have used it for various projects, plus have given a lot of it away.

After launching the first sofa, we noticed that it tended to hang out close to the shore where a turtle might feel vulnerable to land animals, especially the two-legged variety.

After launching the first sofa, we noticed that it tended to hang out close to the shore where a turtle might feel vulnerable to land animals, especially the two-legged variety.